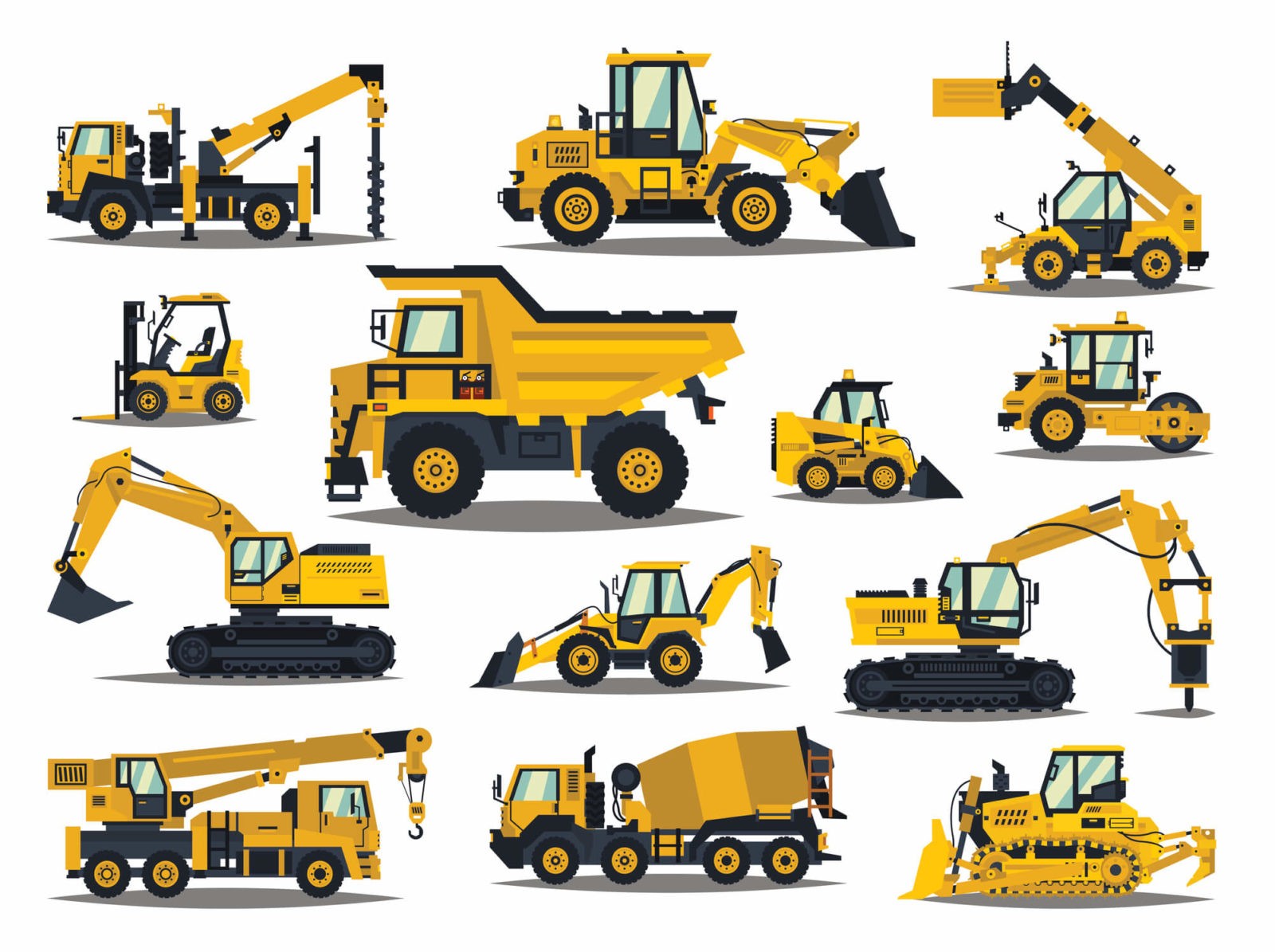

Commonly Made Use Of Building Equipment Parts Explained

Excavator Pail

When thinking about the capability of an excavator, the excavator pail plays a vital function in its general performance and effectiveness. The excavator bucket acts as the main accessory for excavating, lifting, and moving materials on building websites - Aftermarket Construction Equipment Parts. These pails can be found in various shapes and dimensions, each made for specific tasks such as trenching, grading, or heavy-duty digging

The material of the excavator container is commonly constructed from hardened steel to stand up to the rough problems of construction work. The reducing side of the bucket is strengthened to boost sturdiness and reducing performance. Additionally, some buckets feature changeable teeth or sides to make sure simple upkeep and prolonged usage.

The size of the excavator bucket straight influences the device's performance (Aftermarket Construction Equipment Parts). Larger pails appropriate for moving bulk products quickly, while smaller containers provide precision in tight areas. Picking the appropriate bucket size for the work handy is critical for taking full advantage of effectiveness and completing jobs successfully

Bulldozer Blade

The bulldozer blade is an essential component of an excavator's devices, critical for various earthmoving and progressing tasks on construction websites. This big, curved blade connected to the front of the excavator is made to press materials like soil, sand, or particles. Bulldozer blades can be found in different types, such as straight blades for great grading and sloping, U-blades for carrying big tons, S-blades for improved rolling of products, and mix blades for flexibility in different jobs. The angle and position of the blade can typically be adjusted hydraulically, enabling effective control and precision during operation.

Crane Hook

The crane hook, similar to the bulldozer blade in its capability and value on construction websites, functions as an essential component of crane devices for training and delivering heavy materials. This vital component is generally connected to the end of the crane's cable rope to offer a safe and secure connection point for the tons. Crane hooks are made to withstand enormous weights, ensuring the security of both the operators and the products being raised.

The form of the crane hook is meticulously crafted to stop the lots from slipping off throughout transportation. Various kinds of crane hooks are available to accommodate different raising needs, such as C-hooks, S-hooks, and 3 or 4-prong hooks. The size and weight capability of the crane hook have to be carefully matched to the crane's specifications to guarantee ideal efficiency and security.

Normal examination and upkeep of the crane hook are important to avoid accidents and make certain smooth operations on the Continued building website. Any indicators of deterioration must be immediately dealt with to prevent potential risks during lifting operations.

Backhoe Boom

An essential component of backhoe equipment that plays a crucial function in excavation and material handling is the backhoe boom. The backhoe boom is important for getting to deep into trenches or high above the ground to perform various tasks efficiently.

It is typically furnished with a container or various other accessories at the end to help in excavating, training, and lugging products. The convenience of the backhoe boom makes it a valuable device for building and construction, landscape design, agriculture, and various other sectors where excavation and material handling are required.

Dump Truck Bed

Positioned behind a dump vehicle chassis, the dump truck bed acts as the primary container for transferring and discharging different materials on building websites. These beds are available in numerous sizes and shapes, relying on the particular requirements of the task - Aftermarket Construction Equipment Parts. Commonly constructed from steel to endure hefty loads and rough products, dump vehicle beds are made to be durable and resilient

Discard vehicle beds are hydraulically run, permitting them to turn and discharge their components with convenience. This system allows effective and fast discharging of materials such as crushed rock, sand, dirt, or debris at the desired place. The ability to rapidly transfer materials makes dump associate beds important in building jobs where time is of the significance.

Furthermore, discard vehicle beds can be tailored with functions such as side extensions, tarpaulin systems, and tailgates to enhance their capability. These additions aid in securing the lots during transport and avoiding splilling, making sure a safe and reliable transport process on building and construction sites.

Verdict

Finally, comprehending the functions check out this site and elements of generally used building tools components is essential for successful project completion. Excavator pails, excavator blades, crane hooks, backhoe booms, and dump vehicle beds all play necessary duties in numerous construction jobs. By familiarizing oneself with these devices parts, construction specialists can efficiently utilize them to improve performance and efficiency on duty website.

The excavator pail offers as check these guys out the main accessory for excavating, training, and transferring materials on building and construction sites.The material of the excavator bucket is usually made of solidified steel to endure the rough problems of building work.Excavator blades are vital for developing level surfaces, getting rid of particles, and pushing products throughout construction jobs.The crane hook, a lot like the bulldozer blade in its capability and importance on building sites, offers as an essential element of crane equipment for training and delivering hefty products.Positioned at the back of a dump truck chassis, the dump truck bed serves as the primary container for transferring and discharging numerous products on building and construction websites.